This will make installation easier. Installing roofing felt is the first step to shingling the roof deck and is an additional layer of protection for the roof.

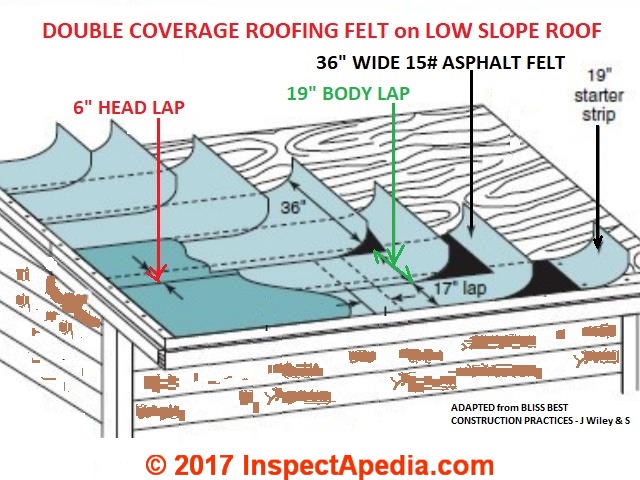

Double Vs Single Layer Felt Underlayment On Roofs

The roofing felt is made up of a paper base impregnated with asphalt.

How to apply roof felt. It can be secured to the wooden roof deck. Cut your felt to size along the marking using a Stanley knife. Remove any debris that may interfere with the installation process.

As you work the paper can be tacked down in the center so it. Laying the second boded underlay felt and adding any gutter drips. All roofing felt is harder to work at low temperature.

Apply the cut felt to either side of the roof pulling it tight so that it lies flat before nailing it at around 10cm intervals along the length of the roof just below the apex. To summarise the system comprises the following. Roll back one half of the length of the sheet to the centre of the roof taking care to maintain the sheet alignment.

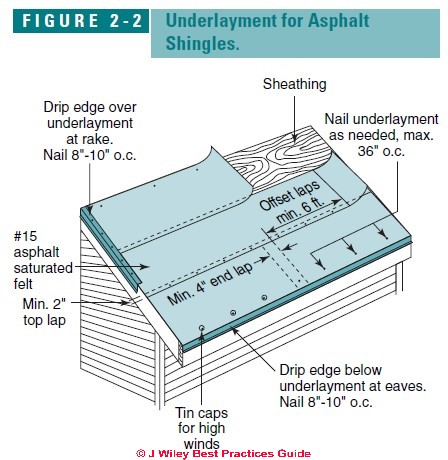

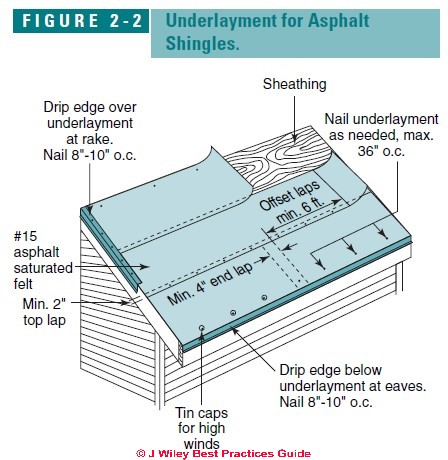

When applying a torch-on felt roofing solution our experts recommend a three-layer system. Measure up the roof and snap chalk lines where the upper edge of each course will go. Roofing felt comes in 15- or 30-pound weight.

The heavier-weight roofing paper is used primarily in northern climates where ice build-up on the roofs edge can be a problem. The roofing felt should be applied in layers that overlap. Includes useful advice on the best materials to use together with information.

Prepare the surface of the shed roof by removing any old roof felt or nails. It helps create a waterproof barrier that keeps moisture from seeping through the shingles to the wood on the roof. The steps are pretty much the same whether its a big roof or a small one.

Run a tape measure along the. The basics of these steps are. Attach your felt with galvanised clout nails - these are shallow enough not to go through the roof.

Applying roof felt paper before the shingles is a necessary step in the roofing process. Felting a flat roof is slightly different from felting a shed or garden outbuilding. Follow the steps below to learn more the basics of roof felt installation and what is required before undertaking this type of roofing project.

Nail it into place before you use the craft knife to cut a slit in the overhang at the roofs apex. Installing shed felt to the roof corners is one of the fiddly parts of the job so if someone is helping you they will be especially valuable at this point. Snap horizontal lines on the roof sheathing to align the upper edge of the felt.

Thicker roof felt paper is better but the price. Venting layer perforated. Ensure the surface is flat clean and dry.

When the roof is dry use a paint roller to apply waterproof paint or primer to the surface to be the adhesive for the felt. Roofing felt or tarpaper is the first layer applied to a new roof of asphalt shingles. Roof felt paper is thick paper impregnated with asphalt and tar.

How do I apply a torch-on felt roofing system for optimum results. The 36 felt should overlap the eave by 38 Snap succeeding lines at 34 inch intervals. Lay out your felt on the roof surface and wait about 30 40 mins before continuing.

Roll out the first course align it tack it down with galvanized nails or staples and cut it to size. Allow no more than 12 inch over the edge of the eave. Use temporary nails to hold the felt while you.

Laying the first underlay felt. This will enable the felt to bond with it more easily. The roofing felt is then applied in accordance with the type of roofing to be used.

Preparing the roof for the felt to be laid. Hammer your nails through the felt into the roof starting at the centre of one side and moving along the edges in 5cm intervals. You can hammer in the nails along the bottom edge of the roof.

Staple down every 6 to 9 inches both top and bottom. Apply the cut felt to either side of the roof pulling it tight so that it lies flat before nailing it at around 10cm intervals along the length of the roof just below the apex. Following the manufacturers instructions apply the adhesive to the first nailed layer.

The second roll should overlap the first a minimum of 9 inches I prefer 12 inches. Once youve secured the side panels in place add the top section to the ridge and fix it using high. In this tutorial Videojug takes you through the necessary tools and easy instructions to installing a felt roll for the roof and other tips to keep in mind.

Start rolling the first layer of felt in the bottom-right or. This follows guidelines which contribute to guarantees. We will assume here that you are using asphalt shingles.

A key factor is the three-layer system can optimise the life expectancy of the roof. Roll out the felt. Use a spirit level or straight edge to scratch a marking into your felt.

If the roof is rotten or damaged you may want to apply a complete new sheet of ply. Place your first layer of felt on the roof and make sure you hold it tightly in place. Start at the bottom of the roofline and work up so any water that gets through the roofing material will shed down the tar paper and will not go under it.

Start by folding the felt down at each corner. Step by step guide on how to apply bituminous roofing felt to your shed roof. Apply felt roof adhesive to the underside of the ridge sheet on both sides and press it into place before nailing it down at 5cm intervals.

Roof felt paper comes in different thicknesses. Complete the finishing touches. Its best to avoid working with it below 10 or in wet or windy conditions.

Fold the felt down along the gable and hammer nails in to secure it at 10cm intervals. Take a width measurement of your roof adding 50-75mm to each side to allow for the overhang of the felt. When felting a flat roof youll add several layers of felt to create a watertight and impenetrable seal.

Installing any verge edge and edging to any flashings and vertical walls. Laying the top bonded layer of felt. Before beginning to felt.

If the roll is not long enough to reach the end start another roll even with the first. Align measure and cut it to length. You can hammer in the nails along the bottom edge of the roof at wider intervals around one every 30cm.

Secure metal flashing at the edges of the roof before primer is applied. Felting a flat roof. How to Install Roofing Felt.

Snap the first line at 35 and 58 inches above the eave.

How To Felt A Shed Roof Fit Long Life Roofing Felt Youtube

Applying Underlayment Better Homes Gardens

How To Properly Install Roofing Felt On A Shed Garage Or House

How To Easily Felt A Shed Roof The Right Way Diy Youtube

Clay Tile Roof Slope Sheathing Underlayment Specifications

How To Attach Roof Felt On A Shed 15 Steps With Pictures

How To Attach Roof Felt On A Shed 15 Steps With Pictures

Installing Roofing Felt In Six Easy Steps Jj Roofing Supplies Jj Roofing Supplies

How To Attach Roof Felt On A Shed 15 Steps With Pictures

Roof Underlayment Requirements Recommendations Is Roofing Felt Necessary

How To Felt A Shed Roof Refelting A Shed Roof Garden Ideas Tips Homebase Youtube

How To Attach Roof Felt On A Shed 15 Steps With Pictures

How To Felt A Shed Roof Youtube

How To Properly Install Roofing Felt On A Shed Garage Or House

Roofing Installing Tarpaper Felt The Basics Dry In Of Mockup Youtube

Roofing Paper And Proper Installation Youtube

The Purpose Of Roofing Felt Is Roofing Felt Necessary Iko Roofing

How To Lay A Three Layer Felt Flat Roof Using Cold Adhesive

Post a Comment

Post a Comment